What Are Imaging Plates?

An imaging plate is a flexible, phosphor-coated sheet of polyester film used to capture and digitize images of various industrial materials. It is an essential component in computed radiography (CR), an imaging technique commonly used in NDT applications.

Understanding how imaging plates work can help you determine whether you need to update your current NDT imaging processes. This post will explain the basics of what imaging plates are, how they work and why they’re important.

The Role of Imaging Plates in Radiography

Imaging plates are flexible, durable plates used in place of X-ray film. You can think of them as digital X-ray plates.

Like traditional film, imaging plates use radiation to capture image information — but that’s where the similarities end. The following processes to read and analyze the images reveal the main differences.

Radiography and Imaging Techniques

The most obvious difference between traditional X-ray imaging and digital radiography techniques like CR is the use of the X-ray plate. Where X-ray film has been around for generations, plate imaging is an innovative NDT technique that enables you to save time and resources, enhance image quality and streamline your analyses. Additionally, digital techniques use advanced software systems to save and analyze scanned images.

Digital and Computed Radiography

Digital forms of imaging, such as CR, simplify the imaging process by eliminating the need for additional processing steps. The more efficient your imaging processes, the faster you can complete testing without sacrificing results.

It’s also important to understand the difference between direct digital radiography (DR) and CR.

DR systems use digital detector arrays (DDAs) instead of cassettes containing a CR image plate. These arrays convert incoming X-rays into electrical charges, which enables you to produce an image in real time. As a result, many businesses treat CR as a transition step toward adopting totally digital systems.

Components and Materials of Imaging Plates

The technical term for a CR imaging plate is a photostimulable phosphor imaging plate, which means it absorbs and emits light to create X-ray images.

Thanks to a dense layer of material that enables photostimulated luminescence (PSL), the plate captures and stores electrical signals in response to radiation exposure.

On most CR imaging plates, the PSL substance is barium fluorohalide (BaFX), a crystalline molecule containing:

- Barium

- Chlorine

- Bromide

- Iodine

- Europium ions

This specific molecular composition enables the plate to absorb and store X-rays during exposure. Then, when the image is scanned and uploaded to the workstation, you can wipe it completely from the plate for future reuse.

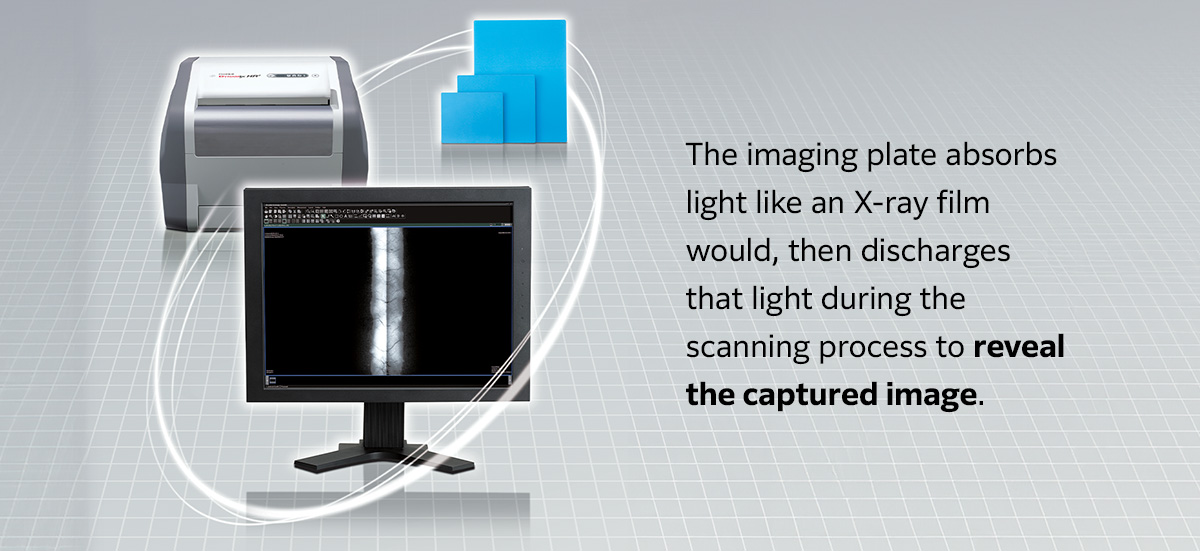

How Imaging Plates Work in Computed Radiography

Imaging plates play a key role in computed radiography. Essentially, the imaging plate absorbs light like an X-ray film would. It then discharges that light during the scanning process to reveal the captured image.

Here’s a brief explanation of what happens at the molecular level:

- Exposure: The europium ions in an imaging plate begin as bivalent ions, which means they are missing two electrons. Exposure to X-rays changes them to trivalent ions, removing one electron from the atoms to create a +3 charge.

- F center formation: When an electron occupies the vacancy in specific crystalline atoms, such as BaFX, it forms an F center. This center absorbs only a specific wavelength of light, causing it to take on that wavelength’s color.

- Luminescence center formation: On an imaging plate, the F center forms when the europium ions replace barium in the BaFX crystal. A luminescence center then forms, which stores X-ray information with the F center.

- Scanning: The scanning light of the CR system excites the phosphor layer, causing the lost europium electrons to travel to the conduction band and reform bivalent ions. They discharge the excess energy as light, which transfers the image to the computer.

- Erasure and reuse: After scanning the image to the computer, the system automatically exposes the plate to prolonged light to erase the data. You can then reuse the plate when needed.

If you are looking for an NDT imaging method that provides a reliable middle ground between traditional film and wholly digital imaging systems, CR is a good place to start. It is compatible with many of the same devices used in conventional X-ray systems, which can help you minimize the upfront cost and generate a strong return on your investment.

The Advantages of Using Imaging Plates

Some of the advantages of using imaging plates over X-ray films include:

- Durability: Imaging plates are significantly more durable than X-ray film, which is fragile and easy to damage.

- More sustainable: You can reuse CR image plates thousands of times, often immediately after erasure. Conversely, conventional X-ray film is only usable once.

- Time savings: Computed radiography eliminates the need to process images in a darkroom, resulting in more efficient scanning.

- Enhanced image quality: Unlike with X-ray film, you can use computed radiography to improve the contrast-to-noise ratio (CNR), remove background noise and capture more details.

- Streamlined analysis: Using the connected computer and software, you can manipulate the images as needed to make identifying defects easier and more accurate.

The biggest drawbacks of using digital radiography techniques rather than traditional film include:

- High upfront investment: While CR systems are often compatible with many of the same components as traditional X-ray technology, the initial cost of the software, plates and workstation hardware can be high for smaller businesses.

- Learning curve: Employees accustomed to using conventional X-ray techniques may encounter challenges when learning to use the updated CR plates.

Inspection Accuracy

Digital radiography can save you valuable time and resources and enhance your ability to identify and investigate defects in various materials.

CR imaging can help you create more accurate NDT images, making it easier to see and inspect defects below the test subject’s surface. Viewing software enables you to adjust the picture as needed so you can more clearly see fine details that may be obscured when using conventional X-ray film.

For example, images on X-ray film are almost impossible to adjust for a clearer look into the test subject — if there are imperfections in the image, you will likely need to make another exposure to improve your visibility.

Enhance Your NDT Imaging Processes With Fujifilm’s Computed Radiography Equipment

Using the right imaging equipment is essential for efficiently identifying defects in sensitive materials and maintaining compliance with key standards. At Fujifilm, our mission is to help businesses obtain the right tools for the job.

As industry leaders in X-ray and digital imaging for NDT applications, we have the knowledge and experience to help you design a system that works best for your business.

Browse our CR imaging products to learn more about our offerings, or fill out our contact form to discuss your imaging needs with a knowledgeable representative. We’ll help you find the right materials for your application.