How Chemical Film Processing Works

Jump to:

- What Is Film Processing?

- What Is Needed to Process X-Ray Film?

- How to Process X-Ray Film

- Alternative to Traditional Film

- Find the Right X-Ray Solution With Fujifilm

When using X-ray films for non-destructive testing (NDT), photo-chemical processing techniques allow us to read the results. Like darkrooms used in film photography, chemical processing helps to make the latent image of an X-ray scan visible.

The process requires several steps and can be sensitive to timing, humidity and other characteristics. It works well for some businesses and doesn’t require complex equipment, but many organizations benefit from digital film technologies, which could offer more efficiency and advanced software solutions.

Both processes rely on some kind of processing technique. Let’s take a look at chemical film processes and how their digital counterparts compare.

What Is Film Processing and How Does it Work?

In industrial radiography methods, radioactive waves create a “hidden” or latent image in a sheet of X-ray film. The film is made up of a blue-tinted base sandwiched between two emulsion coatings, which contain radiation-sensitive silver halide crystals. The emulsion can also contain additives and gelatin. When hit by radioactive waves, the crystals in the emulsion get rearranged, creating the latent image.

The newly exposed grains are more sensitive to the chemicals in the developer, which causes the image to appear. The exposure process then gets stopped, and the unexposed silver halide crystals are removed. After a final wash and dry, the film is ready for viewing and storage.

X-ray film processing can occur manually or automatically. Manual X-ray film processing involves dipping the film into tanks with each solution and drying them securely. Automatic processing uses film processor equipment to move through the steps and monitor the chemicals involved. The processors can automatically monitor and adjust the levels of solution and store multiple cycle configurations for easy development.

What Is Needed to Process X-Ray Film?

You can process X-ray film in a few different ways, but the basic chemicals required include:

- Developer: High-contrast processing often uses hydroquinone as its developer, while low-contrast processing might use phenidone or Metol, short for N-methyl-p-aminophenol, or equivalent developing agents. Developer also contains an alkali to control the acidity, a preservative like sodium sulfite and a restrainer such as potassium bromide, which prevents the developer from acting on unexposed silver and creating fog.

- Stop bath: A stop bath solution is acidic, so it can stop the alkaline developer from continuing its reactions. Acetic acid is common in stop baths, but you can also find potassium or sodium metabisulfite. The solution typically dilutes these chemicals to about 2-3%.

- Fixing solution: This solution removes unexposed silver from the film to ensure a clear image. The fixing agent itself is usually sodium and/or ammonium thiosulfate. The solution also contains a hardener such as potassium alum, which hardens the emulsion, a preservative like sodium sulfite and an acidifier, like sulfuric or acetic acid, which helps remove any leftover alkalinity from the previous step. You could also use a fixer neutralizer after fixing to help reduce the amount of water needed and speed up the washing stage.

- Wetting agent: A wetting agent helps prevent water spotting and uneven drying in manually processed films. These issues could cause watermarks to show up on the finished product and result in longer drying times.

X-ray processing also requires water and an appropriate environment for development to occur, such as a darkroom with processing tanks or an automated system. X-ray processing chemicals for automated systems may have different compositions than manual processing materials. You may also need cleaning solutions to wash the equipment.

Steps for Manually Processing X-Ray Film

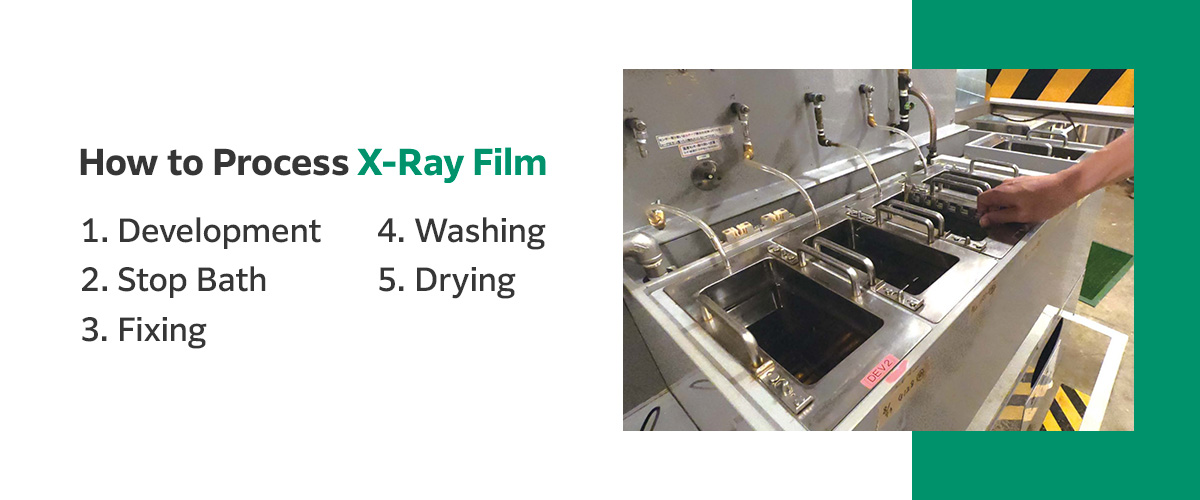

X-ray film processing involves exposing the film to chemicals in specific stages and timeframes. The correct order of steps in manual processing is as follows:

1. Development

First, you must expose the film to the developer for the length of time specified by the manufacturer. Typically, this timeframe is around six to seven minutes, but some films need more or less, and the temperature can affect the time required, too. Shake the film in horizontal and vertical paths for a few seconds at a time while it develops.

2. Stop Bath

Immerse the film in the stop bath solution according to the manufacturer’s instructions. The acid stop bath will halt development and prevent the silver from becoming too dense and creating an inconsistent image.

3. Fixing

The film then gets dipped in the fixing solution to remove any extra silver halide that would obscure the image. The fixing agent converts the silver halides into soluble compounds and hardens the emulsion. Again, follow manufacturer instructions regarding time and agitation requirements.

If desired, you can then use a fixer neutralizer to improve the efficiency of the next step. It makes washing faster and requires less water.

4. Washing

The washing step can vary in several ways, including temperature and flow. Follow your instructions and wash the films in batches to remove residual chemicals. Pay special attention to this step for archival images, which can fade over time if the solutions stick around.

5. Drying

Apply a wetting agent to your films before setting them out to dry. It prevents water spots from appearing on the film and supports consistent drying. You can dry industrial X-ray films in still air at the temperature recommended by the manufacturer.

Alternative to Traditional Film

Although manual X-ray film processing is a tried-and-true technique, more modern options are available, too. Digital radiography (DR) offers a digital version of chemical film processing. Digital radiography can be Computed Radiography (CR) which utilizes Image Plates also with a latent image instead of film which can be used several times to be scanned by a reader or It can use digital detector arrays (DDAs), which are flat panels you can use to collect an image and process it through a computer in real-time. Instead of rearranging crystals, X-ray radiation gets converted into an electrical charge, which a detector sensor can read and turn into a digital image.

DR methods are clear, precise and high in quality. They benefit from the addition of computer processing technologies, such as defect-recognition software and analytic tools. These programs help provide DR’s exceptional signal-to-noise ratios and linearity. The digital nature of the images makes them incredibly easy to share, store and secure. They won’t fade or get lost over time, and you don’t need to dedicate humidity-controlled space to storing them.

DR is used in many industries, from product evaluations in aerospace manufacturing to casting and weld inspection in architectural applications. Traditional film can be sensitive and requires careful chemical development and consumables that will need to be replaced. DR can greatly simplify the development process, virtually eliminating consumables and variability. You can even use it in the field, making it a portable option. It’s a good choice for high-volume operations.

Find the Right X-Ray Solution With Fujifilm

Fujifilm has been at the forefront of imaging technology for decades, with a collection of dependable chemical and DR X-ray solutions. We offer affordable NDT technology to fit your operation and the expertise to help you find the right equipment. Whether you’re looking for efficiency, precision or advanced software systems, we can help you get the ideal solution in place.

As a longtime imaging pioneer, Fujifilm is your source for state-of-the-art X-ray technologies, including film, chemicals and digital systems. Learn more about our NDT solutions, or contact us today to talk with a representative.