What Is a Non-Destructive Testing (NDT) Technician?

Jump to:

- What is an NDT Technician?

- How to Become an NDT Technician

- Skills Required for an NDT Technician

- NDT Technician Career Outlook

Non-destructive testing (NDT) technicians are in high demand across various industrial and engineering fields. A career as an NDT inspector may be the right choice if you are a detail-oriented problem solver with a strong work ethic and excellent communication skills. You must also be highly knowledgeable and extensively trained in the various NDT methods and tools. The job market for these professionals is always growing and evolving along with technological advances. Learn what NDT technicians do, why they’re important and how you can become one.

Understanding the Role of NDT Technicians

An NDT technician plays a pivotal role in assuring the safety and dependability of materials across diverse industries. The term NDT refers to the methods, tools and general field of non-destructive testing.

In this role, you use various techniques to inspect materials, structures, components and systems for structural flaws without compromising or damaging them. Some of these flaws include cracks, corrosion, imperfections and defects that impair the materials’ functionality, strength and stability.

NDT technicians are indispensable to the manufacturing sector to ensure that products meet strength, integrity and reliability properties. They conduct material testing without disassembling the item, offering economical solutions and upholding safety benchmarks.

NDT technicians serve vital roles in the manufacturing world. An NDT technician may have alternative titles, such as:

- NDT inspector.

- Non-destructive examination technician (NDE).

- Non-destructive inspection technician.

At the same time, there are various career paths NDT technicians can pursue depending on their level of experience. For example, entry-level NDT technician positions include assistant quality control inspectors and technicians, while years of experience unlock positions such as industrial radiographers, quality control or quality assurance inspectors.

How Does Destructive Testing Vary From Non-Destructive Testing?

Non-destructive testing preserves the material the technician is evaluating. These methods inspect for internal and external flaws without dismantling or damaging the material or structure. On the other hand, destructive testing may damage or destroy the material. For instance, destructive testing might involve taking apart a section of material, applying tensile strength to gauge a reaction or bending a material to test flexibility.

Destructive testing methods are used on sample materials specifically set aside for testing. Non-destructive testing methods have many advantages over destructive testing methods, including:

- Produces less material waste because it doesn’t destroy materials.

- Is cost-efficient because it preserves test specimens.

- Results in minimal downtime because materials can be tested while still in use.

- Produces highly accurate and reliable results.

What Does an NDT Technician Do?

NDT inspectors use various imaging technologies such as industrial radiography, ultrasonic imaging or assisted defect recognition. With these imaging tools and a trained eye, the technician can find imperfections without damaging or taking apart the material. The ability to do so is useful across many different industries, including:

- Aerospace

- Oil and gas

- Manufacturing

- Engineering

- Troubleshooting

- Scientific research

- Automotive

- Power generation

- Welding and fabrication

Why Are NDT Technicians Important?

NDT inspectors are critical for manufacturing to ensure consistency in product quality. In engineering, NDT technicians ensure the proper maintenance of infrastructure to avoid catastrophic accidents. As a result, they help preserve resources and protect human safety. While there are many ways you can test an object for defects, non-destructive methods are the most time- and cost-effective.

An NDT technician’s non-intrusive methods mean they need not disassemble structures, which is how they differ from destructive testing technicians. Many industries benefit from NDT methods, which help produce the best results. For instance, NDTs facilitate testing pipes carrying hazardous substances like oil and nuclear elements. They also prevent accidents in essential industries like infrastructure, automotive, oil refinery and transportation.

How to Become an NDT Technician

If you’re interested in serving the essential role of an NDT inspector, you’ll need the proper education, training and certification. To pursue this career, you will need to meet the following NDT technician requirements:

- High school diploma or equivalent

- Formal classroom NDT training

- On-the-job training

- Specific industry training, if desired

- Passing scores on certification exams

An NDT career is ideal for anyone who doesn’t want to pursue a traditional post-secondary degree. Some NDT technicians earn two or four-year degrees, but it’s possible to have a successful career without an associate’s or bachelor’s degree. Entry-level positions may provide additional training, but higher-level NDT technician positions often require years of experience in the field.

To work as a certified NDT inspector, you must undergo all necessary training and pass all related certification exams. Most NDT training programs take less than one year to complete, although you can find two- to four-year NDT technology degree curriculums. A background in science, engineering, technology and mathematics (STEM) is always beneficial.

What You’ll Learn in Training

You need formal education to set a foundation for a career as an NDT technician. During your NDT technical training, you’ll learn how to perform all relevant job duties with hands-on, guided instruction and on-site training. You’ll experience using impurity-detection tools, which involve various technologies. The tools you’ll use will depend on the relevant field. You’ll also learn about safety and compliance standards across industries.

When you study NDT, you learn various testing methods like:

- Visual testing by looking at assets or using remote visual inspection devices.

- Radiography testing using X-ray generators or radioactive isotopes.

- Leak testing using pressure gauges, listening devices, or soap bubble examination.

- Acoustic emission testing by looking at acoustic energy bursts.

- Liquid penetrant testing utilizes ultraviolet light and fluorescent or visible dye.

- Magnetic particle testing involves reviewing the material’s magnetic field flow.

NDT Technician Job Description

NDT technician’s job roles and responsibilities are similar regardless of the industry you’re working in. A typical day in the life of an NDT technician involves:

- Setting up and calibrating NDT testing equipment.

- Using NDT techniques to perform rigorous tests on structures and materials.

- Determining corrosion, surface defects, fatigue and hidden flaws on the material’s surface.

- Interpreting and analyzing test results to ensure the materials are safe and ready for use.

- Performing additional tests in case the initial results are inconclusive.

- Preparing and distributing test reports by creating design drawings with detailed descriptions.

- Creating plans for repairing damaged materials and structures.

- Developing safety processes and procedure checklists.

- Training other NDT technicians.

- Demonstrating proper testing machinery and materials.

Skills Required for an NDT Technician

NDT professionals have certain soft and hard skills that enable them to perform their job duties. It’s a good idea to consider the skills you need to succeed as an NDT technician — doing so will also help you see if you’d be a good fit for the role.

Soft Skills

Succeeding as an NDT technician requires certain soft skills. Consider whether you have the disposition and temperament to do well in this field. Here are some skills and characteristics helpful to a career as an NDT technician:

1. Analytical Attention to Detail

NDT inspectors must be able to discern small details and variations when performing evaluations. It’s essential to be detail-oriented and have strong analytical skills in this field because even tiny imperfections can have serious consequences in manufacturing and engineering. An eye for detail can preserve materials and ensure human safety. Attention to detail also requires strong near-sight vision and keen observational and analytic skills.

2. Problem-Solving Capabilities

These professionals are expert problem-solvers. You must be able to notice and address problems as they arise because the fundamental purpose of an NDT technician is to identify and address problems before they worsen.

3. Strong Communication Skills

Strong communication skills are vital to enable NDT technicians to communicate complicated technical information easily, especially to those not well-versed in the field. They must share all essential details without leaving anything out.

Additionally, they need strong reading comprehension and active listening skills when working with clients or colleagues. Working alongside others is a regular part of the job. Among surveyed NDT inspectors, 90% said they have face-to-face conversations daily, and 70% say they have phone conversations daily. So, you’ll need to be an effective and comfortable communicator to do well in this role.

4. Ability to Work On-Site

A career as an NDT technician is not a desk job. Instead, you will work in a warehouse or outside. You’ll have to stand, walk, bend, liftor carry testing equipment. You’ll need hand dexterity and steadiness to deal with small parts and pieces. You should be comfortable working as much as needed to get the job done — most technicians say they work more than 40 hours in an average week.

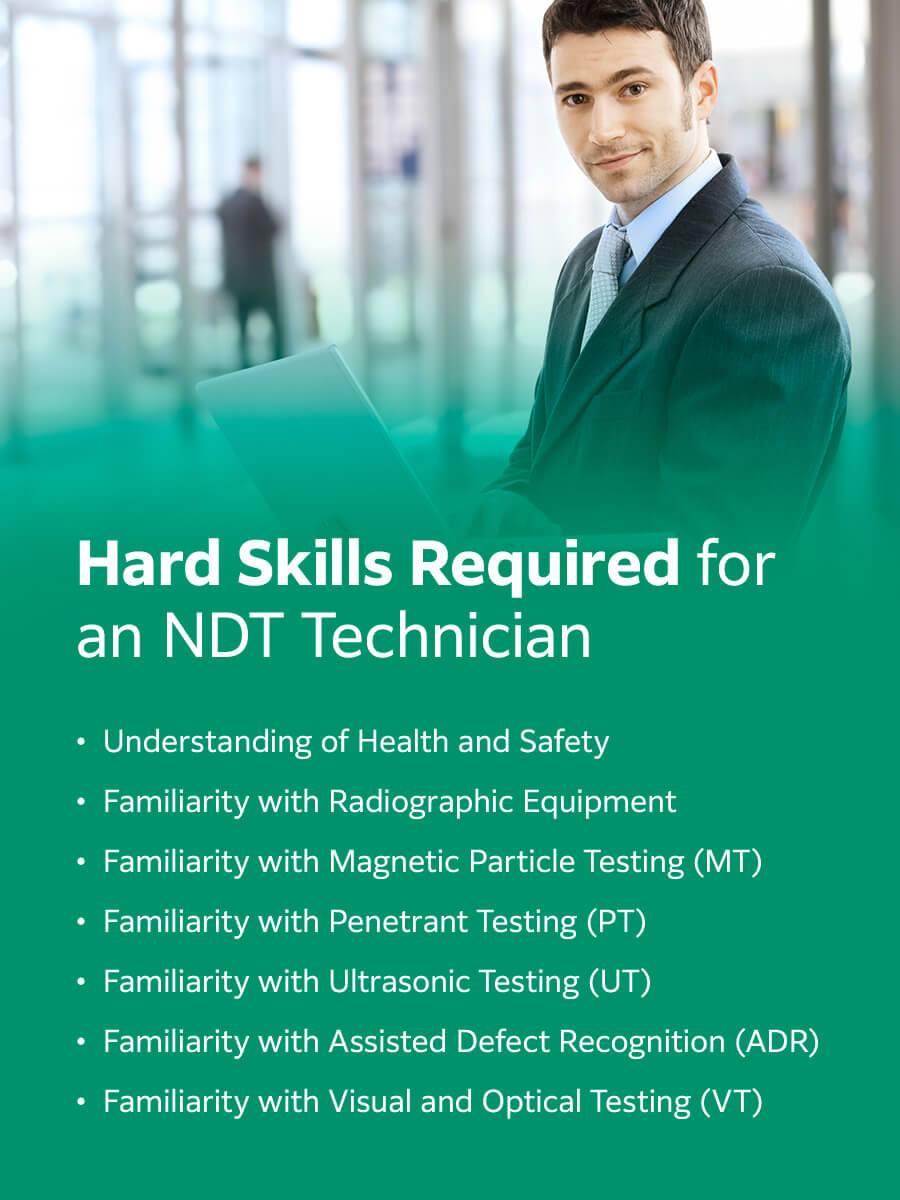

Hard Skills

The hard skills you’ll need as an NDT technician vary depending on your industry. NDT inspectors use various tools and methods depending on what materials they’re evaluating and the industry in which they’re working. They may need to be able to choose the right equipment for the task at hand.

The following hard skills are the most common ones you’ll need in this field:

1. Understanding of Health and Safety

Anyone in this role must have a thorough understanding of issues related to health and safety. You must be well-versed in health and safety concerns as they pertain to manufacturing and engineering. You should also know the industry standards, such as those the American Society of Mechanical Engineers sets for construction equipment and components. That way, you can find defects that pose health and safety risks.

2. Familiarity With Radiographic Equipment

Most NDT technicians use radiographic equipment every day. Radiographic equipment allows the specialist to visualize the inside of equipment without taking it apart or otherwise destroying it — it’s part of what defines non-destructive testing. In the same way that a medical doctor uses an X-ray to look for bone fractures, NDT inspectors use X-rays or gamma rays to look for impurities in a structure. The image is projected onto a film or digital detection device for examination.

3. Familiarity With Magnetic Particle Testing (MT)

Another method for finding defects is magnetic particle testing (MT). The technician creates a magnetic field through an object. They then dust iron particles over the object’s surface. Any cracks at or just below the object’s surface will disrupt the magnetic field and cause the iron particles to flood to that location. An iron particle buildup indicates an imperfection, which the technician will flag.

4. Familiarity With Penetrant Testing (PT)

Penetrant testing (PT) is a simple and efficient way to search for surface-level defects. You may also see PT referred to as “dye penetrant inspection” or “liquid penetrant inspection.” PT involves applying a dye solution to an object’s surface, which will seep into any impurities.

After removing the dye, the technician applies a developer. It draws out any dye penetrating the surface through a crack or crevice. If the dye is fluorescent, ultraviolet light can make it stand out. Otherwise, the technician will use a stark color contrast in the penetrant dye and the developer to make it easier to see. An NDT technician may need to be able to perform this type of test.

5. Familiarity With Ultrasonic Testing (UT)

Another method is ultrasonic testing (UT), in which sound waves provide information rather than visual cues. The tester transmits high-frequency sound waves into a material. If the sound waves hit a change in medium, they bounce back to the receiver, allowing the technician to determine thicknesses and find impurities. This form of testing works well on metals, plastics and ceramics but not wood materials. One of its common uses is to identify pipework corrosion.

6. Familiarity With Assisted Defect Recognition (ADR)

Assisted defect recognition (ADR) software is a useful tool for finding defects. The system processes images and helps the technician find impurities. ADR technology helps technicians identify issues with stronger reliability. Every NDT technician should know how to use ADR software.

7. Familiarity With Visual and Optical Testing (VT)

The simplest way to find surface-level impurities is through visual and optical testing (VT). With their knowledge of impurities and careful attention to detail, an NDT technician might evaluate a surface visually. They’ll use lighting tools, such as flashlights and measuring tools. They might also use computer-controlled cameras or optical aids, such as a borescope, to help them find features.

NDT Technician Career Outlook

NDT technicians enjoy lucrative careers with desirable salaries. The field is rising as technological methods continue to evolve and expand. Non-destructive testing is useful in many different industries, as it helps manufacturers save time, money and resources while ensuring quality control. Because the testing methods are so versatile and useful, you can find plenty of different places of employment as an NDT technician. Thanks to an expanding job market, you’ll also earn a competitive salary.

NDT Technician Salary

As of May 2023, engineering technologists like NDT technicians earned an average of $75,290 annually. The median wage was slightly less at $73,500. Since it’s a median wage, about half of technicians earn more, and half earn less. Keep in mind that median wages vary by state. For instance, in Pennsylvania, the median wage is lower than the national median at $66,720 per year. Of Pennsylvanian technicians, about 10% earn more than $103,000.

On the other hand, technicians in California tend to earn about $78,910, which is above the national median. About 10% of workers earn more than $122,010. It’s important to note how the cost of living and inflation rates vary between different states — most jobs pay a bit more in California, where the cost of living is higher than average.

Job Market Outlook

The job market for quality control professionals is on the rise. By 2032, projections suggest the market will see 2,300 new jobs. This growth rate is about as fast as average for the job market overall and shows plenty of opportunities for those pursuing the field in the next decade.

Learn More About Our NDT Testing Solutions

The need for non-destructive quality testing continues to expand because it allows manufacturers and other professionals to save time and resources. As a result, NDT professionals enjoy a strong job market and competitive wages. An NDT technician is an expert in utilizing NDT testing tools to identify defects and inform their partners and clients of their findings.

NDT specialists use the latest technological solutions to find manufacturing defects in national defense, aerospace, oil and gas and other vital industries to make the world safer. Contact us today if you want to learn more about NDT testing solutions.

At Fujifilm, our leading radiographic imaging technology brings exceptional accuracy to every inspection. Our in-house software exceeds expectations. As a leader in non-destructive testing technology, we provide the tools and expertise necessary for reliable inspections.